Phone :+86-18122867790

TEl:+86-0755-27927879

E-mail:pm@vilva-test.com

vilva@vilva-test.com

URL: www.vilva.nethttps://vilva.en.alibaba.com

Battery discharge steps:

1. Before discharging, you should charge the battery pack in advance to make the battery pack fully charged.

2. Record battery pack float voltage, cell float voltage, load current, ambient temperature, and other settings for the rectifier (or switching power supply) Parameters, and check that all screws are tightened.

3. Determine the discharge rate of the battery pack as needed

4. During the discharge process, considering the accuracy of the current meter display on the dummy load is insufficient, the clamp current meter is required to detect the discharge current.

5. For a newly installed battery pack, the discharge end condition is that the battery pack discharge capacity reaches the rated capacity requirement or there is one monomer in the battery pack to 1.80V.

6. For the situation during discharge, if the discharge is terminated, the capacity discharged by the battery pack is not calculated to meet the specified rated capacity.

Quantity, the battery capacity of the battery pack may have problems, should be promptly contact the relevant manufacturers to deal with.

7. At the end of the discharge, first let the dummy load empty, then disconnect the battery pack from the dummy load, and connect the battery to the switching power supply.

It should be noted that the voltage difference between the battery pack and the rectifier that has been discharged is large, and sparking may occur when connecting. It is better to lower the switch first.

The float voltage of the power supply makes the floating voltage of the switching power supply as close as possible to the open circuit voltage of the battery pack to reduce the spark.

8. If the discharge condition is normal, observe and record the start of charging. If the discharge condition is not normal, monitor the charging status of the battery pack to keep the battery charged properly.

Battery discharge precautions:

1. Install the battery correctly. If the battery is incorrectly installed in the reverse direction, a short circuit or charging may occur, resulting in battery temperatu, The degree of rapid increase.

2, do not short the battery

3. Do not attempt to charge the battery.

4. Do not force the battery to discharge.

5. Do not mix old and new batteries or batteries of different models and brands.

6. Do not heat or solder the battery directly.

7. Do not disassemble the battery.

8. Do not deform the battery.

9. Do not put the battery in a fire.

10. Do not let children touch the battery or replace the battery without adult supervision.

11. Do not seal or change the battery.

12. For unused batteries, they should be stored in their original packaging and kept away from metal materials. If the packaging is already open,Orderly discharge, do not mess up stacking.

13. Unless it is used in an emergency, batteries that have not been used for a long time should be taken out of the electrical device as much as possible.

Attachment: Introduction to discharge equipment

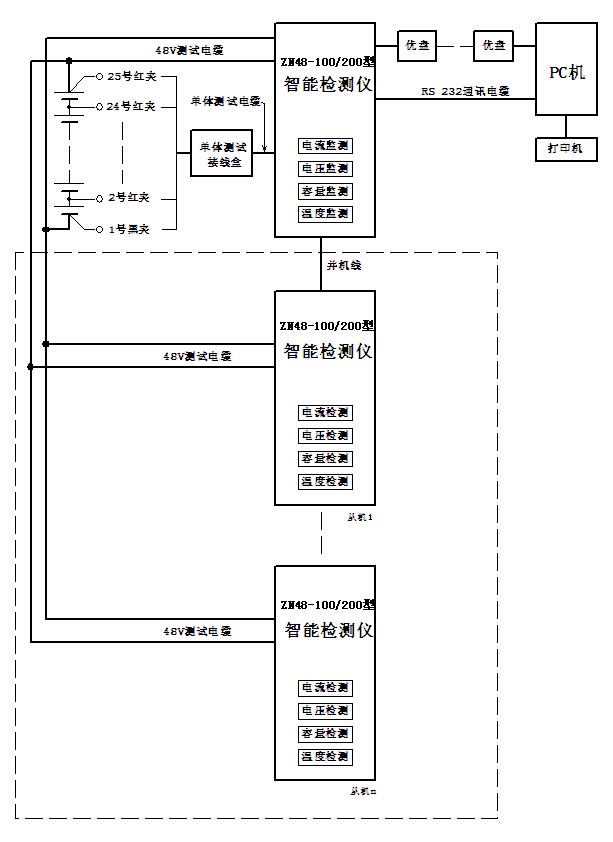

1, system structure

The detector consists of four parts:

(1) Electric heating device part: It adopts pure resistance wire load bar, which has good linearity and precise control, which makes the detector work more stable and reliable.

(2) Control part: adopt high-reliability single-chip system to realize data acquisition and current closed-loop regulation of current, voltage and temperature.

Complete the automatic control function of the whole machine.

(3), panel part: LCD display, Chinese menu prompt, display all test data in real time;

Parameter settings and control operation commands are entered by the keyboard.

(4) Data processing part: dump the battery measurement data to the microcomputer, and display the print discharge data curve and table.

2. Technical parameters and indicators

(1), parameters

No. Indicator Name Technical Specifications

1 Connect the load voltage DC 48V ±15%

2 rated discharge current 100A & 200A

3 current adjustment fineness 1A

4 constant current discharge control accuracy 1%

5 total voltage measurement accuracy 1%

6 cell voltage measurement accuracy ±10mV

7 Timer Timing (0 to 17 hours, 1 minute accuracy)

8 working power supply AC 220V ± 10%

9 Physical characteristics 100A: 385mm × 235mm × 520mm, weight 18KG

200A: 550mm × 250mm × 580mm, weight 28KG

(2) Electromagnetic compatibility characteristics: It complies with the relevant regulations in YD/T 983-1998.

(3), safety performance

Insulation resistance: 1000 V DC voltage is applied between the input terminal of the detector and the casing (ground), and the insulation resistance should be greater than 20 MΩ.

Withstand voltage: the tester's working power supply and the measured AC power input terminal should be able to withstand 50Hz, 2000V between the outer casing (ground)

The current voltage is 1 min, the leakage current is less than 10 mA, and there is no breakdown or arcing.

Temperature rise: When the detector is working normally for a long time, the maximum temperature rise of the surface of the load is not more than 180K.

Anti-transport vibration performance: Meet the requirements of Grade 3 in GB/T 6587.6-1986.

(4), working environment

Working temperature -10 ° C ~ +50 ° C

Relative humidity ≦80%

Altitude 3000 meters (Ultra high deduction)

Storage temperature -30°C ~ +70°C

(5), power supply

Working voltage: 220V variation range 187~242V

Power consumption: ≤1.8 kW

3, product features

● Microcomputer control with high measurement accuracy.

● Through the keyboard, you can set the discharge current, discharge duration, minimum discharge voltage of single or whole battery, discharge capacity, current time, local address and other parameters.

● Real-time monitoring function: high degree of intelligence, real-time display and control of various set parameters (such as voltage, current, time...), automatic test, automatic constant current control, unattended.

● Automatic protection function: It has four kinds of threshold alarms and automatic protection for battery pack and single battery minimum protection voltage, discharge capacity and discharge time, and has high temperature and power failure alarm.

● Data transfer function: The test data of this instrument can be transferred by USB flash drive. Each USB flash drive can record 100 sets of data (each group of 24 batteries discharges for 17 hours). Then the data is transferred to the microcomputer, and the data is processed to display the print data curve and the table, thereby visually distinguishing the advantages and disadvantages of each battery.

● It can be directly connected to the PC to realize real-time monitoring of the computer.

● Parallel function: 2-11 single units can be operated in parallel to increase the discharge current, up to 1100A & 2200A.

● Small size, carefully designed and using the latest high-quality power consumption devices, the machine is much smaller than the previous models, and it is the latest replacement product.

The modular structure of the series of testers makes the overall volume significantly reduced, easy to operate, easy to maintain, and easy to carry. It provides scientific testing methods for users with different needs. It is the safety guard for emergency power supply equipment, so you can worry about using electricity! Products are now widely used in electric power, communications, railway, coal, military, aerospace, finance, hospitals, hotels and other industries, and are becoming an indispensable tool for DC emergency power supply acceptance and maintenance.

Shenzhen VILVA Electronic Technology Co. Ltd.

Business Address: 2nd Floor,Building A2,Songhu Zhigu R&D Center,Liaobu Town,Dongguan City, Guangdong Province, P.R.C

Factory Address: 2nd Floor,Building A2,Songhu Zhigu R&D Center,Liaobu Town,Dongguan City, Guangdong Province, P.R.C

Phone: +86-18122867790

Contact:Amy

Fax Number: 086 0755 29768581

Wechat ID:shenzhenvilva

WhatsApp:+86-15814356357

Skype:live:809b341254f5b3b8

E-mail: pm@vilva-test.com

3525878530@qq.com

Vilva high-voltage load bank i...[2013-08-21]

Vilva high-voltage load bank i...[2013-08-21] Shenzhen Vilva Electronic Tech...[2013-08-21]

Shenzhen Vilva Electronic Tech...[2013-08-21] Discussion on Measurement Meth...[2013-08-21]

Discussion on Measurement Meth...[2013-08-21] Generator unit daily load test...[2013-08-21]

Generator unit daily load test...[2013-08-21] Three Advantages of Choosing V...[2013-08-21]

Three Advantages of Choosing V...[2013-08-21] Vilva Electronics promotes loa...[2013-08-21]

Vilva Electronics promotes loa...[2013-08-21] Instructions for purchasing a ...[2013-08-21]

Instructions for purchasing a ...[2013-08-21] Various types of AC load bank ...[2013-08-21]

Various types of AC load bank ...[2013-08-21] What is ATE?Shenzhen Weierhua ...[2013-08-08]

What is ATE?Shenzhen Weierhua ...[2013-08-08] |

Copyright@ Shenzhen Vilva Electronics Co., Ltd. Copyright 2013 www.vilva.net tel:0086-755-27927879 fax:0755-29768581 Contact:Amy +86-18122867790 E-mail:pm@vilva-test.com Add:2nd Floor,Building A2,Songhu Zhigu R&D Center,Liaobu Town,Dongguan City, Guangdong Province, P.R.C |

|